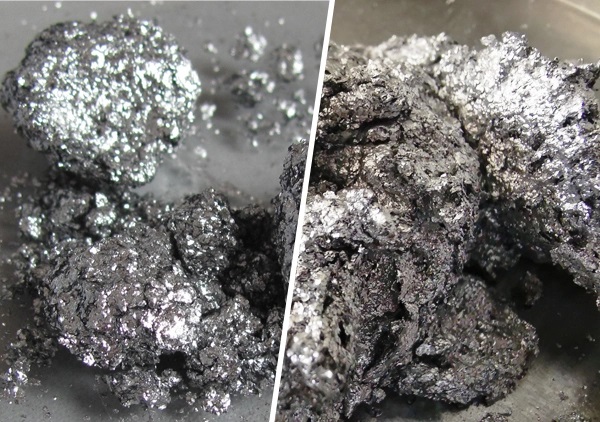

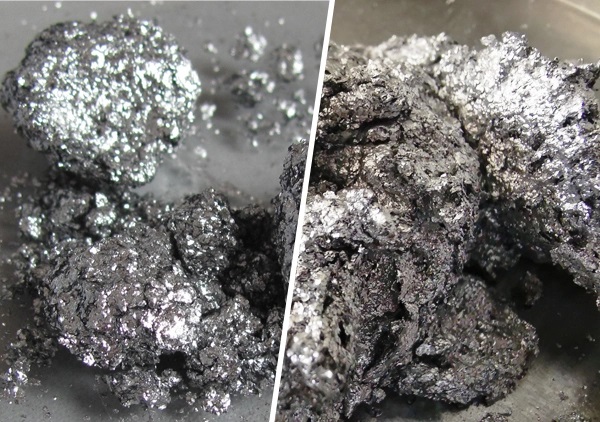

Aluminum paste has emerged as a highly valuable ingredient in the formulation of paints and coatings, offering a multitude of advantages that enhance both the functional and aesthetic aspects of these products.

One of the most prominent advantages of aluminum paste is its ability to impart a stunning metallic luster to paints and coatings. The tiny aluminum particles within the paste reflect light in a unique way, creating a shiny and eye - catching appearance. This property is highly sought after in various applications, such as automotive coatings, where a luxurious and glossy finish can significantly enhance the vehicle's overall appeal. In the architectural sector, aluminum - based coatings on building facades can give a modern and elegant look, making the structure stand out in the urban landscape.

Aluminum paste also has the remarkable ability to enhance the colors used in paints. It can make colors appear more vibrant and intense. When combined with pigments, it can create unique visual effects, such as a pearlescent or iridescent look. This allows for greater creativity in color formulation, enabling manufacturers to produce coatings with special color effects that are not achievable with traditional pigments alone. For example, in decorative paints for interiors, the addition of aluminum paste can transform a simple color scheme into a sophisticated and luxurious design.

Aluminum paste exhibits excellent covering power. A relatively small amount of the paste can cover a large surface area effectively. This is due to the high refractive index of the aluminum particles and their ability to scatter light. In paint formulations, this means that less material is required to achieve the desired level of coverage. This not only reduces the cost of raw materials but also makes the application process more efficient. For industrial coatings, where large areas need to be covered quickly, the high - covering - power property of aluminum paste is particularly advantageous.

The covering power of aluminum paste also helps in hiding surface imperfections. It can effectively conceal minor scratches, dents, or other flaws on the substrate being coated. This is crucial in applications where a smooth and flawless appearance is desired, such as in high - quality furniture coatings or in the refinishing of vehicles. By using aluminum paste, manufacturers can ensure that the final coated surface looks perfect, even if the underlying substrate has some minor defects.

Aluminum paste can contribute to the corrosion - resistance properties of paints and coatings. Aluminum itself has a natural resistance to oxidation, and when incorporated into a coating system, it forms a protective layer on the substrate. This layer helps to prevent the underlying material from being exposed to corrosive elements such as moisture, oxygen, and chemicals. In marine coatings, for example, the use of aluminum paste can significantly extend the lifespan of the coating by reducing the rate of corrosion on metal surfaces exposed to seawater.

Another aspect of durability enhanced by aluminum paste is its ability to provide some degree of UV resistance. The reflective nature of the aluminum particles helps to deflect UV rays, reducing the amount of UV radiation that penetrates the coating. This can slow down the degradation process of the coating caused by UV exposure, such as fading, chalking, and cracking. In outdoor coatings, such as those used on bridges or in exterior building applications, this UV - protecting property of aluminum paste is of great value in maintaining the long - term integrity and appearance of the coating.

Aluminum paste can improve the thermal conductivity of coatings. In some applications, such as in heat - dissipating coatings for electronic components or in industrial equipment where heat management is important, the ability of the coating to conduct heat can be crucial. The aluminum particles in the paste act as heat conductors, allowing heat to be transferred more efficiently through the coating. This can help in preventing overheating of the underlying components or materials, thereby improving the overall performance and lifespan of the equipment.

In certain cases, the electrical conductivity of the coating is also a desirable property. Aluminum is a good electrical conductor, and when used in paints and coatings, it can provide a conductive path. This is useful in applications such as electromagnetic interference (EMI) shielding coatings, where the coating needs to block or absorb electromagnetic waves. By incorporating aluminum paste into these coatings, manufacturers can achieve the required level of electrical conductivity to effectively protect against EMI.

In conclusion, the use of aluminum paste in paints and coatings offers a wide range of advantages, from enhancing the visual appeal and color properties to improving durability, covering power, and even providing thermal and electrical conductivity. These benefits make aluminum paste an indispensable component in many paint and coating formulations across various industries.