Aluminum pastes play a crucial role in various industries due to their unique properties. The two main types, floating and non-floating aluminum pastes, have distinct characteristics.

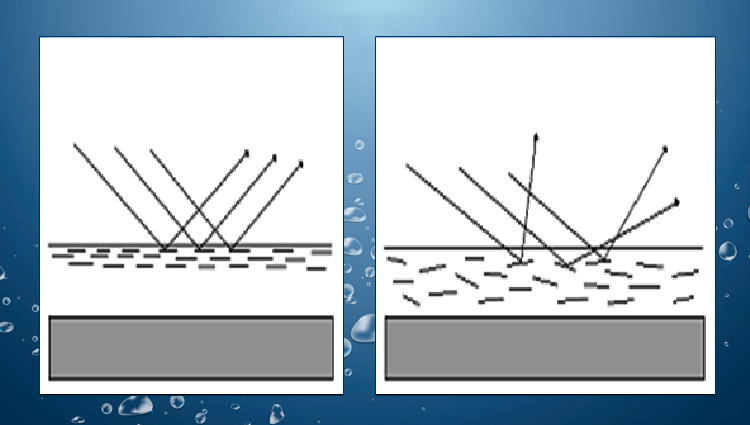

Floating aluminum pastes have a special quality that allows the aluminum flakes to float on the surface of the coating. This gives a highly reflective and mirror-like finish. They are excellent for applications where a bright, metallic sheen on the surface is desired. For example, in the production of some metallic paints for automotive or decorative purposes, the floating type can create a striking visual effect. The flakes align themselves parallel to the surface, maximizing light reflection.

On the

other hand,

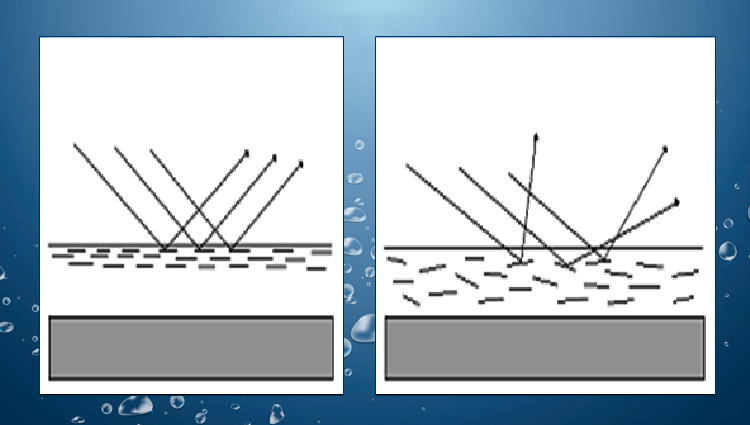

non-floating aluminum pastes are designed to be evenly dispersed throughout the coating. They provide a more uniform and subtler metallic appearance. This type is often used in applications where a smooth, integrated metallic look is needed, such as in industrial coatings or certain types of inks. Non-floating pastes offer better hiding power and are less likely to cause settling issues compared to the floating varieties.

In terms of particle size and shape, floating aluminum pastes usually have larger and more regular flakes, which contribute to their surface-floating ability and enhanced reflectivity. Non-floating pastes may have a more diverse range of particle sizes and shapes, optimized for dispersion and adhesion within the medium.

Both floating and non-floating aluminum pastes have their own advantages and are selected based on the specific requirements of the end product. Understanding their differences helps users make the right choices for achieving the desired aesthetic and functional results.