Water-based aluminium paste is an important material in various industries, and its quality plays a crucial role in the performance and application effects of the final products. Several factors contribute to determining the quality of water-based aluminium paste.

The size and distribution of aluminium particles have a significant impact on the quality of the water-based aluminium paste. Finer particles generally result in a smoother and more uniform appearance in the applied coatings. They also tend to have better hiding power and can provide a more delicate metallic luster. A narrow particle size distribution is desirable as it ensures consistent optical and physical properties throughout the paste. If the particle size distribution is too wide, it may lead to uneven coating surfaces, with some areas appearing rougher or having different reflective intensities.

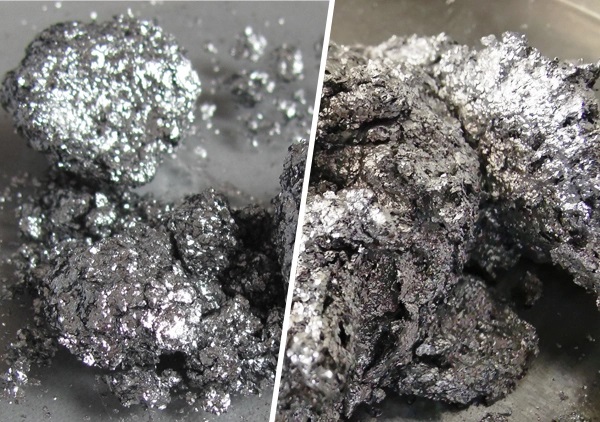

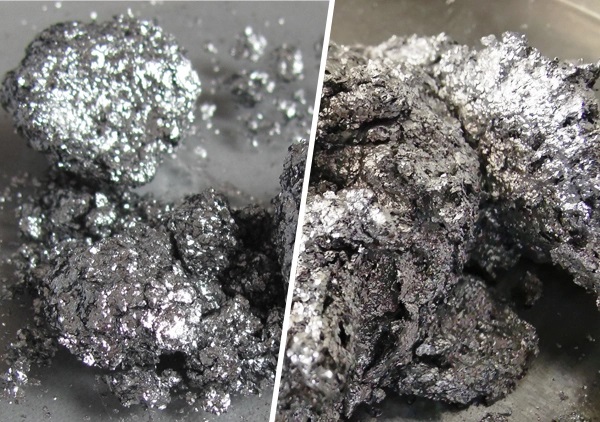

The shape of the aluminium particles also matters. Spherical or near-spherical particles are often preferred as they can pack more densely and provide better flowability in the water-based medium. Irregularly shaped particles may cause difficulties in dispersion and can affect the overall quality and stability of the paste. Moreover, the particle shape can influence the light scattering and reflection characteristics, thereby affecting the visual appearance of the final coating.

The choice of surfactants and dispersants is crucial for maintaining the dispersion stability of water-based aluminium paste. These additives help to prevent the aluminium particles from aggregating and settling over time. They adsorb onto the particle surfaces, creating a repulsive force that keeps the particles separated. The right combination and dosage of surfactants and dispersants can ensure that the aluminium paste remains homogeneous and stable during storage and application. If the dispersion stability is poor, the aluminium paste may separate into layers, with the particles settling at the bottom, which can lead to inconsistent application results and a decrease in quality.

The pH value and electrolyte concentration of the water-based system also affect the dispersion stability. A suitable pH range is necessary to maintain the charge balance on the particle surfaces and the stability of the dispersing agents. Deviations from the optimal pH can cause the particles to flocculate or coagulate. Similarly, high electrolyte concentrations can compress the electrical double layer around the particles, reducing the repulsive forces and leading to instability. Therefore, careful control of the pH value and electrolyte concentration is essential to ensure the dispersion stability of the water-based aluminium paste.

The ability of the water-based aluminium paste to adhere firmly to the substrate is a key quality factor. Good adhesion ensures that the coating remains intact and durable over time, even under different environmental conditions. It is affected by the surface properties of the substrate, the formulation of the paste, and the application method. A proper pretreatment of the substrate, such as cleaning and surface activation, can improve adhesion. Additionally, the presence of appropriate binders and additives in the water-based aluminium paste can enhance its adhesion to various substrates, including metals, plastics, and ceramics.

Water-based aluminium paste is often used in applications where resistance to corrosion and oxidation is important. The quality of the paste can be evaluated by its ability to protect the underlying substrate from these processes. This depends on the purity of the aluminium particles and the presence of any protective coatings or additives. High-quality water-based aluminium paste may contain inhibitors or passivation agents that can slow down the corrosion and oxidation rates. In contrast, a poor-quality paste may lead to rapid deterioration of the coating and the substrate, reducing the lifespan of the final product.

The drying time and film formation characteristics of the water-based aluminium paste also influence its quality. A suitable drying time is necessary to ensure efficient production processes and good film quality. If the drying time is too long, it can lead to productivity issues and may increase the risk of contamination during the drying process. On the

other hand, if the drying time is too short, it may cause incomplete film formation, resulting in a porous or uneven coating. The ability of the paste to form a smooth, continuous, and defect-free film is essential for achieving good coating performance and appearance.

The quality of the raw materials used in the production of water-based aluminium paste is fundamental. High-purity aluminium sources and quality additives are essential to ensure the overall quality of the final product. Any impurities in the raw materials can affect the properties of the aluminium particles and the performance of the paste. For example, impurities may lead to inconsistent particle sizes, reduced metallic luster, or decreased stability. Therefore, strict quality control of the raw materials is crucial in the manufacturing process.

The parameters during the manufacturing process, such as the milling and dispersion techniques, temperature control, and mixing times, also have a significant impact on the quality of the water-based aluminium paste. Optimal process parameters can ensure that the aluminium particles are evenly dispersed, the coatings have the desired properties, and the product quality is consistent. Any deviations in these parameters can result in variations in the quality of the paste, such as differences in particle size distribution, dispersion stability, or coating performance.

Regular quality testing and monitoring are essential to ensure the quality of water-based aluminium paste. This includes tests for particle size distribution, dispersion stability, coating adhesion, and other relevant properties. By conducting these tests at different stages of production and during storage, any potential quality issues can be detected early, and appropriate corrective actions can be taken. Quality control measures also help to maintain the consistency and reliability of the product, ensuring that it meets the required standards and customer expectations.

In conclusion, the quality of water-based aluminium paste is determined by a combination of factors related to the aluminium particles, dispersion stability, coating performance, and the manufacturing process and quality control. Understanding and controlling these factors are essential for producing high-quality water-based aluminium paste that can meet the diverse needs of various industries and applications.